FIELDS OF ACTIVITY

Tooling and Machining

In the field of hybrid and steel mold manufacturing, we are among the industry leaders with our innovative techniques and expertise in precision machining and sheet metal forming processes. By focusing on digital transformation and innovation, we are a pioneer when it comes to error-free production with our fully automated lines.

Norm Tooling

Established in 2003, Norm Tooling started mold production for Fasteners and machining special parts in 2006. Norm Tooling, which aims to provide high quality, economically priced and the best just-in-time (JIT) service, provides services in machining and cold forging molding with its new generation production technologies, modern and comprehensive machine park, and well-trained staff.

Established in 2 areas, it operates in a total of 10.000 m2 indoor facility with 250 employees, with 300 employees target for 2022. Norm Tooling has the potential to produce 400,000 molds annually as of 2020.

Contact: +90 (232) 328 13 30

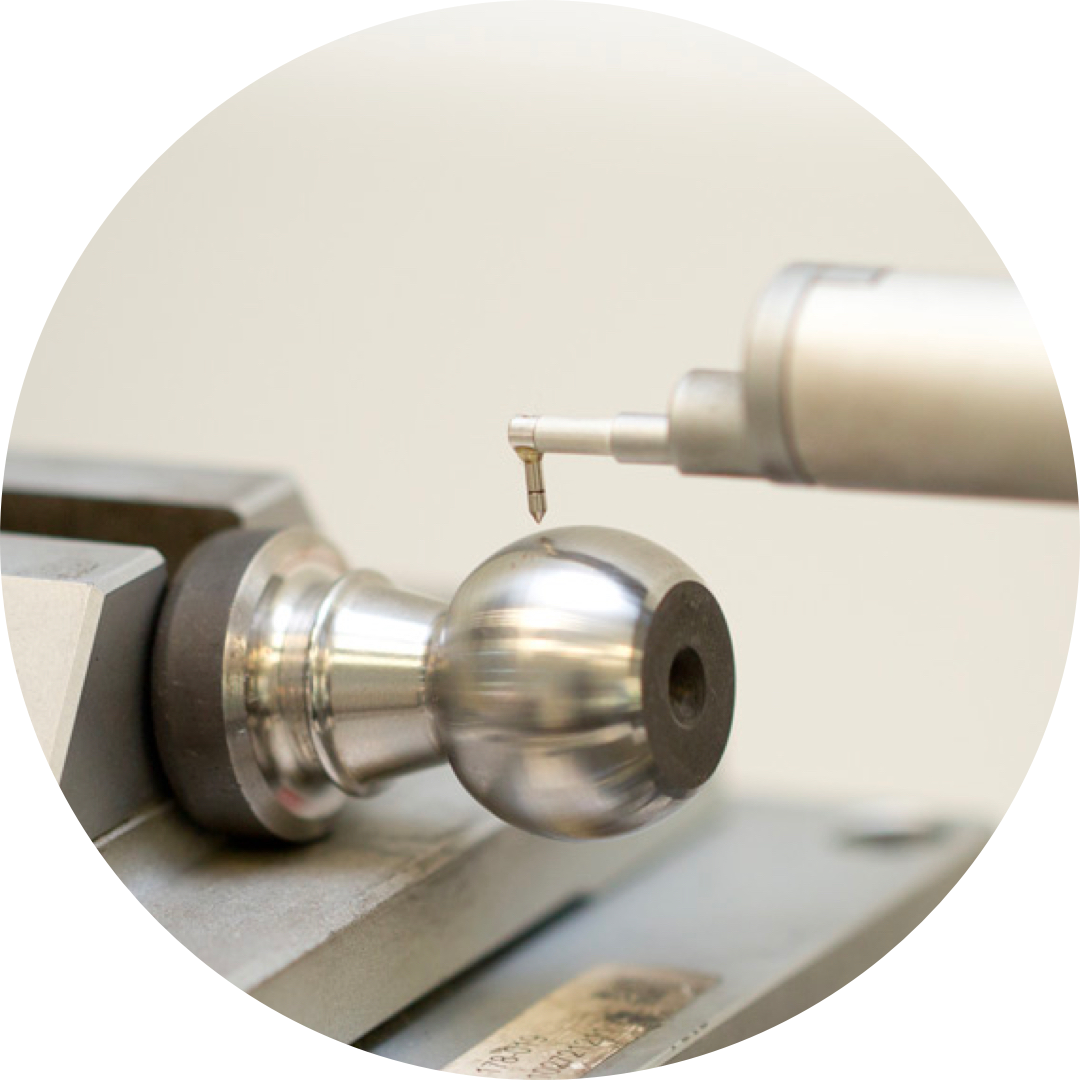

Machining

Machining processes are planned with a fully automated setup. Processing can be carried out both on cold-formed products and from raw material to the finished product. With our expert team and industry experience, we design fully automated production lines tailored to specific products, capable of high-volume manufacturing using various raw materials, from copper to titanium alloys, in line with customer needs. All operations, from raw material processing to the final product, inspected through 100% camera-controlled sorting, are performed seamlessly with robotic handling systems, ensuring a completely hands-free process.

Contact: +90 (232) 328 13 30